Longos Cakes Menu: A Comprehensive Overview (Updated May 3, 2026)

Discover the latest Longos cakes menu details, including options for convenient PDF downloads and easy online browsing for delightful desserts and pastries.

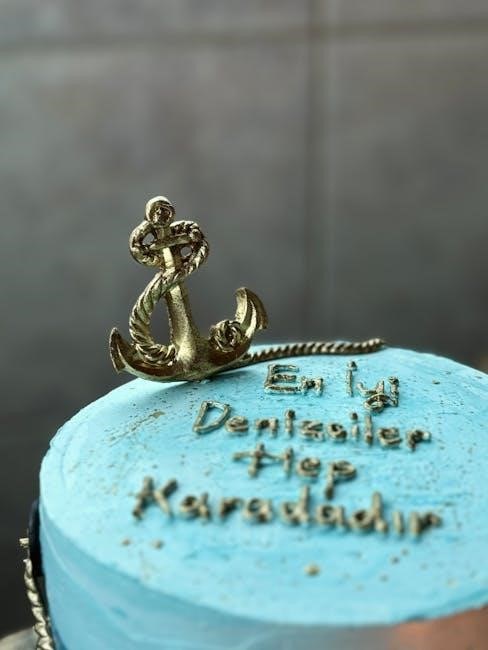

Longos Cakes have become a beloved staple for celebrations and everyday indulgences across the Toronto/GTA region, renowned for their quality ingredients and delectable flavors. From classic Real Cream Bar Cakes to rich New York Style Cheesecakes, Longos offers a diverse selection to satisfy every sweet craving.

Customers frequently seek the Longos Cakes menu PDF to conveniently browse available options and pricing from home. While a dedicated, downloadable PDF isn’t prominently featured on the Longos website as of today, May 3, 2026, accessing the menu is remarkably straightforward. The complete cake assortment, along with current prices, is readily available through Longos’ online grocery delivery platform, Voilà by Longos, and via third-party delivery services like Uber Eats, specifically in areas like Brampton.

This comprehensive overview will guide you through navigating the Longos Cakes menu, detailing popular choices, pricing, delivery options, and how to check product availability, ensuring a seamless and satisfying experience.

Where to Find the Longos Cakes Menu (PDF & Online)

Currently, Longos does not offer a single, centralized Longos Cakes menu PDF for direct download. However, accessing the complete and up-to-date cake selection is easily achievable through several online avenues. The most comprehensive resource is the Voilà by Longos online grocery platform, where you can browse all available cakes, view detailed product information, and check real-time pricing.

Alternatively, customers in the Brampton and surrounding areas can explore the Longos menu on Uber Eats. This platform displays a selection of available cakes with corresponding prices, facilitating convenient ordering for delivery.

For the latest pricing (as of May 3, 2026), direct access through these platforms is recommended. While a dedicated PDF isn’t available, these online resources provide a dynamic and accurate representation of the Longos Cakes menu.

Popular Longos Cake Options

Longos delights customers with Real Cream Bar Cakes, New York Style Cheesecakes, and convenient cake slices, readily available for order and enjoyment.

Longos Real Cream Bar Cakes

Longos’ Real Cream Bar Cakes represent a classic indulgence, offering a rich and satisfying dessert experience for cake lovers across the Toronto/GTA region. Currently featured are two incredibly popular varieties: the decadent Chocolate Real Cream Bar Cake and the delightfully fruity Black Forest Real Cream Bar Cake, each weighing 500g.

As of today, May 3, 2026, both the Chocolate and Black Forest options are priced at $17.54 per cake. These cakes are easily added to your cart through Longos’ online grocery delivery service, providing a convenient way to satisfy your sweet cravings. They are also available via third-party delivery apps like Uber Eats, specifically in areas like Brampton and surrounding locales. These bar cakes are a staple, consistently praised for their creamy texture and flavorful profiles, making them a go-to choice for celebrations or simply a delightful treat.

Chocolate Real Cream Bar Cake (500g) ⎼ Price & Details

Indulge in Longos’ exquisite Chocolate Real Cream Bar Cake, a 500g delight perfect for chocolate enthusiasts. This cake boasts a rich, creamy chocolate filling layered within a moist and tender base, creating a harmonious blend of textures and flavors. As of May 3, 2026, the price is a very reasonable $17.54 per cake, making it an accessible luxury for any occasion.

Customers can conveniently add this delectable treat to their online grocery order through Longos’ delivery service, enjoying delivery within the Toronto/GTA area, sometimes as quickly as one hour. Alternatively, it’s available through third-party platforms like Uber Eats, particularly in Brampton and nearby regions. This cake consistently receives positive reviews, celebrated for its intense chocolate flavor and satisfyingly creamy texture – a true classic!

Black Forest Real Cream Bar Cake (500g) ⎼ Price & Details

Experience the timeless elegance of Longos’ Black Forest Real Cream Bar Cake, a 500g masterpiece blending chocolate and cherry flavors. This cake features layers of rich chocolate cake, light and airy whipped cream, and juicy cherries, creating a delightful symphony of tastes. Currently priced at $17.54 (as of May 3, 2026), it’s an affordable indulgence for any celebration or a simple treat.

Longos offers convenient options for acquiring this cake, including direct delivery throughout the Toronto/GTA region, with potential for delivery in as little as one hour. Customers can also find it on third-party delivery apps like Uber Eats, especially in Brampton and surrounding areas. The Black Forest cake is a customer favorite, praised for its balanced sweetness and the perfect combination of chocolate and cherry – a truly classic dessert!

Longos New York Style Cheesecakes

Indulge in the creamy decadence of Longos’ New York Style Cheesecakes, a signature offering renowned for its rich texture and classic flavor profile. Available in generous 600g portions, these cheesecakes are perfect for sharing or savoring individually. Longos presents two exquisite variations: the traditional Original New York Style Cheesecake and the vibrant Cherry New York Style Cheesecake, both crafted with premium ingredients.

Currently, the Cherry New York Style Cheesecake is priced at $12.14 (as of May 3, 2026), while the Original version is also available. Customers can conveniently order these cheesecakes through Longos’ grocery delivery services across Toronto and the GTA, or via third-party platforms like Uber Eats, particularly in areas like Brampton. These cheesecakes represent a delightful addition to any dessert spread, promising a truly satisfying experience.

Cherry New York Style Cheesecake (600g) ─ Price & Details

Experience the delightful fusion of creamy New York style cheesecake and sweet, tart cherries with Longos’ 600g Cherry New York Style Cheesecake. This exquisite dessert features a smooth, rich cheesecake base swirled with a vibrant cherry filling, creating a harmonious balance of flavors. As of May 3, 2026, this cheesecake is priced at $12.14 per cake, offering exceptional value for a premium dessert experience.

Customers can easily add this cheesecake to their online grocery order through Longos’ delivery services in the Toronto/GTA area, or conveniently order via third-party apps like Uber Eats, especially in Brampton and surrounding regions. It’s a perfect choice for celebrations or simply indulging in a moment of sweet bliss. Don’t miss out on this classic treat!

Original New York Style Cheesecake (600g) ─ Price & Details

Indulge in the timeless classic with Longos’ Original New York Style Cheesecake, a 600g masterpiece of creamy, decadent perfection. This cheesecake boasts a rich and velvety texture, crafted with premium ingredients to deliver an authentic New York cheesecake experience. As of today, May 3, 2026, the price for this delightful treat is currently listed at $12.14 per cake, representing excellent value for a high-quality dessert.

Longos offers convenient options to enjoy this cheesecake, including grocery delivery throughout Toronto and the GTA, and ordering through popular third-party apps like Uber Eats, particularly accessible in Brampton and nearby areas. Perfect for any occasion, or simply a personal indulgence, this cheesecake is a guaranteed crowd-pleaser. Add it to your cart today!

Longos Cake Slices & Individual Servings

Enjoy a taste of Longos’ signature cakes with convenient, individual slices like the Vanilla Custard option, priced at $3.49 for an 80g serving;

Longos Cake Slice ─ Vanilla Custard (80g) ─ Price & Details

Indulge in a delightful single serving of Longos’ Vanilla Custard Cake Slice, a perfect treat for those moments when a full cake is simply too much. Each slice weighs 80 grams and is currently priced at $3.49. This translates to a cost of $4.36 per 100g, offering a convenient and affordable way to savor the classic Longos flavor.

This individual slice provides a taste of the creamy vanilla custard filling and light, fluffy cake that Longos is known for. It’s an ideal option for a quick dessert, a small celebration, or simply satisfying a sweet craving. Easily accessible through Longos’ grocery delivery services, including Voilà Online Groceries, and available via third-party apps like Uber Eats in areas like Brampton, this slice is a convenient choice for enjoying a Longos favorite.

Pricing Breakdown: Vanilla Custard Slice (per 100g)

Understanding the cost per unit allows for informed purchasing decisions, and Longos provides a clear breakdown for their Vanilla Custard Cake Slice. Currently, the 80g slice is priced at $3.49. To determine the price per 100g, a simple calculation reveals a cost of $4.36. This detailed pricing structure ensures transparency for customers comparing portion sizes and overall value.

This per-100g pricing is particularly useful when considering larger orders or comparing with other dessert options. Longos’ commitment to clear pricing extends across their entire bakery selection, making it easy to budget and enjoy their delicious treats. Whether purchasing through Longos’ grocery delivery, Voilà Online Groceries, or via platforms like Uber Eats, the consistent pricing ensures a seamless shopping experience and predictable costs for this popular vanilla custard slice.

Ordering Longos Cakes for Delivery

Enjoy convenient cake delivery through Longos’ grocery services in Toronto/GTA, or utilize third-party apps like Uber Eats for quick access!

Longos Grocery Delivery Services (Toronto/GTA)

Longos provides a seamless grocery delivery experience throughout the Toronto and Greater Toronto Area (GTA), bringing their delectable cake selection directly to your doorstep. Customers can conveniently order their favorite Longos Real Cream Bar Cakes – Chocolate and Black Forest (500g each) – alongside other grocery essentials. The New York Style Cheesecakes, available in Cherry and Original flavors (600g each), are also readily available for delivery.

To initiate an order, simply visit the Longos online grocery platform. Be mindful of the minimum order requirement of $35.00 to qualify for delivery. Delivery timeframes can vary, with options available for as little as one hour, ensuring your sweet cravings are satisfied promptly. Explore promotions and regularly updated offerings to enhance your experience. Sign in or register to begin browsing and building your perfect order today!

Delivery Timeframes & Minimum Order Requirements

Planning your Longos cake delivery is straightforward, with options designed to fit your schedule. While specific timeframes can fluctuate based on location and order volume within the Toronto/GTA, Longos aims to deliver groceries, including their popular cakes, in as little as one hour. This rapid delivery service ensures fresh baked goods arrive promptly for any occasion.

However, to utilize the Longos grocery delivery service, a minimum order requirement of $35.00 must be met. This ensures efficient delivery routes and cost-effectiveness. Customers can easily browse the online menu, adding various items to reach this threshold. Remember to check the website or app for the most up-to-date delivery slot availability and any potential surcharges.

Ordering via Third-Party Apps (e.g., Uber Eats)

For added convenience, Longos cakes are also accessible through popular third-party delivery applications like Uber Eats. This provides an alternative ordering channel, particularly useful for those seeking immediate gratification or preferring a different platform experience. The Longos menu on Uber Eats showcases a selection of their delectable cakes, including the Real Cream Bar Cakes and New York Style Cheesecakes.

Currently, Uber Eats delivers from Longos locations in Brampton and surrounding areas. Users can easily browse the available cake options, view pricing – which may differ slightly from direct Longos delivery – and place their orders directly through the app. Be sure to check for any applicable delivery fees or promotions offered through Uber Eats to maximize your savings and enjoy a sweet treat delivered to your door.

Longos Menu on Uber Eats ─ Brampton & Nearby Areas

The Longos menu available on Uber Eats for Brampton and nearby regions features a curated selection of their popular cake offerings. Customers can conveniently order items like the Chocolate Real Cream Bar Cake (500g) for $17.54, and the Black Forest Real Cream Bar Cake, also priced at $17.54 per cake. Cheesecake lovers can indulge in the Cherry New York Style Cheesecake (600g) at $12.14, or the Original New York Style Cheesecake for the same price.

It’s important to note that pricing and availability on Uber Eats are subject to change and may differ slightly from prices found directly on the Longos website or through their grocery delivery service. Users should always verify the current prices and ensure the desired cake is in stock before finalizing their order. Delivery fees and service charges from Uber Eats will also apply.

Longos Cakes: Pricing & Availability

Current prices, as of May 3, 2026, range from $12.14 to $17.54 per cake; online checks confirm product availability easily.

Current Prices for Featured Cakes (as of May 3, 2026)

As of today, May 3rd, 2026, Longos offers a delectable selection of cakes at competitive prices. The Longos Real Cream Bar Cake, Chocolate (500g) is currently priced at $17.54 per cake, providing a rich and satisfying chocolate experience. For those who prefer a classic flavor, the Longos Real Cream Bar Cake, Black Forest (500g) is also available for $17.54 each.

Moving onto cheesecakes, the Longos New York Style Cheesecake, Cherry (600g) is a delightful option at $12.14, offering a tangy and sweet combination. The traditional Longos New York Style Cheesecake, Original (600g) is similarly priced at $12.14.

For a smaller indulgence, the Longos Cake Slice ─ Vanilla Custard (80g) is available for $3.49, priced at $4.36 per 100g. These prices are subject to change, so checking the latest updates online is always recommended.

Checking Product Availability Online

To ensure your desired Longos cake is in stock before heading to the store or placing an order, utilizing the online availability checker is highly recommended. The Longos website and affiliated grocery delivery platforms, such as Voilà Online Groceries, provide real-time inventory updates for each product. Simply search for the specific cake you’re interested in – whether it’s the Chocolate Real Cream Bar Cake or a New York Style Cheesecake – and select your preferred store location.

The system will then display whether the item is currently available, low in stock, or out of stock. This feature is particularly useful for popular items or during peak seasons. Remember to refresh the page for the most accurate information, as availability can change rapidly. Checking online saves time and prevents disappointment!

Additional Longos Bakery Items

Beyond exquisite cakes, Longos Bakery offers a tempting array of pastries and desserts, complementing their celebrated cake selection beautifully.

Beyond Cakes: Other Pastries & Desserts Available

Longos Bakery extends far beyond its impressive cake selection, presenting a delightful assortment of pastries and desserts to satisfy every sweet craving. Customers can explore a range of options, including freshly baked cookies, delicate tarts, and rich chocolate brownies. Their pastry case frequently features seasonal specialties, offering unique flavors throughout the year.

Don’t overlook the individual dessert cups, perfect for a quick treat or portion control. Longos also provides a selection of European-style pastries, such as croissants and pain au chocolat, ideal for breakfast or an afternoon snack. These additional offerings complement the cakes perfectly, making Longos a one-stop destination for all bakery needs. Exploring these options enhances the overall dessert experience.

Seasonal Cake Offerings & Promotions

Longos frequently introduces limited-time seasonal cake offerings, aligning with holidays and special occasions throughout the year. Expect festive flavors during Christmas, Easter, and Valentine’s Day, often featuring unique decorations and ingredients. Summer brings lighter, fruit-forward options, while autumn showcases warm spice combinations.

Keep an eye out for promotional deals and discounts on select cakes, often advertised through their online menu, weekly flyers, and in-store displays. Longos also occasionally runs promotions tied to their grocery delivery services, offering reduced delivery fees or special cake bundles. Regularly checking the Longos website or app is the best way to stay informed about current seasonal offerings and available promotions, maximizing your savings.