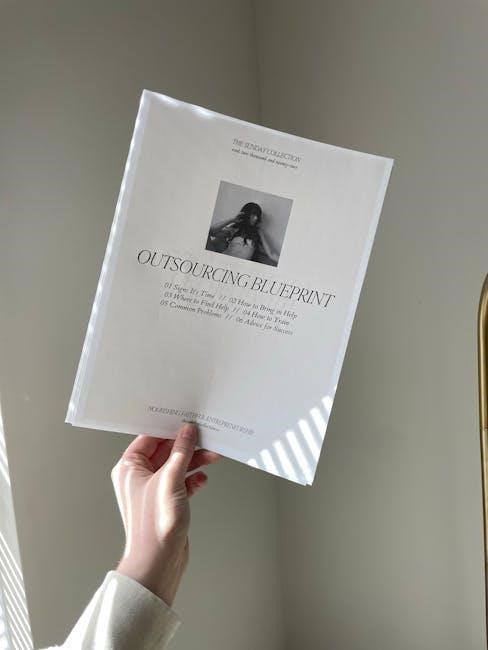

The 2010 Honda Accord manual is a comprehensive guide essential for optimal vehicle performance, safety, and longevity. It covers operation, maintenance, troubleshooting, and technical specifications.

Overview of the 2010 Honda Accord

The 2010 Honda Accord is a midsize car available in sedan and coupe styles, offering reliability, fuel efficiency, and a spacious interior. It features a range of engine options, including a 2.4L and 3.5L V6, and is known for its smooth handling and comfortable ride. With advanced safety features and a reputation for durability, the Accord remains a popular choice for drivers seeking a balance of performance and practicality.

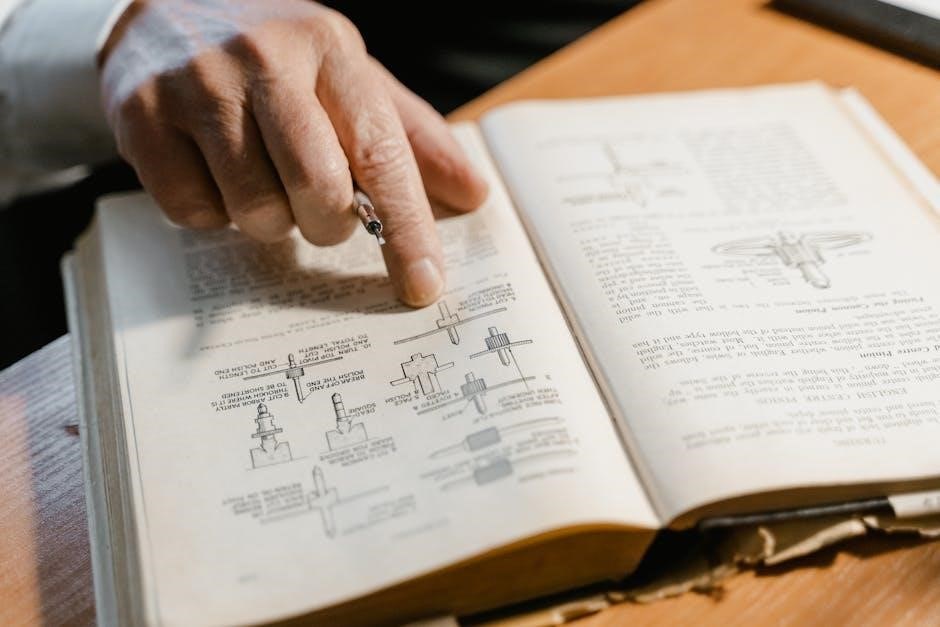

Importance of the Owner’s Manual

The owner’s manual is a vital resource for understanding and maintaining the 2010 Honda Accord. It provides detailed instructions on operation, maintenance, and troubleshooting, ensuring optimal performance and longevity. By following the manual, drivers can prevent damage, optimize fuel efficiency, and enhance safety. It also serves as a troubleshooting guide, helping owners identify and address common issues efficiently, making it an indispensable companion for Accord owners.

Engine and Performance

The 2010 Honda Accord features a powerful and efficient engine, designed for smooth acceleration and reliable performance, ensuring a balanced blend of fuel efficiency and driving satisfaction.

Engine Specifications

The 2010 Honda Accord offers two engine options: a 2.4-liter inline-4 cylinder producing 177 horsepower and a 3.5-liter V6 delivering 271 horsepower. Both engines are paired with a 5-speed manual or automatic transmission. The inline-4 achieves 22 MPG city and 31 MPG highway, while the V6 provides 19 MPG city and 28 MPG highway. These engines ensure a balance of power and fuel efficiency.

Fuel Recommendations

The 2010 Honda Accord manual recommends using regular unleaded gasoline with an octane rating of 87. For optimal performance, avoid using lower-octane fuel, as it may cause engine knocking. The V6 models may benefit from mid-grade or higher octane for better efficiency. Always consult the manual for specific fuel recommendations tailored to your Accord’s engine type and driving conditions to ensure peak performance and fuel efficiency.

Transmission and Drivetrain

The 2010 Honda Accord offers a 5-speed manual or automatic transmission, providing smooth shifting and efficient performance. The drivetrain is front-wheel drive, ensuring stability and control.

Transmission Types

The 2010 Honda Accord features two transmission options: a 5-speed manual and a 5-speed automatic. The manual offers precise control and fuel efficiency, while the automatic provides smooth, effortless driving. Both transmissions are designed for optimal performance, ensuring a responsive and enjoyable driving experience with the Accord’s powerful engine capabilities and refined drivetrain.

Drivetrain Overview

The 2010 Honda Accord features a front-wheel-drive (FWD) drivetrain, designed for efficiency and reliability. It includes a driveshaft and axles that deliver power from the transmission to the front wheels; This setup optimizes fuel economy and provides responsive handling, making it ideal for both city and highway driving conditions while ensuring a smooth ride.

Features and Options

The 2010 Honda Accord offers a range of features, including comfortable seating, advanced technology, and optional upgrades. It is available in sedan and coupe styles.

Interior Features

The 2010 Honda Accord manual highlights a spacious and ergonomic interior with premium materials. Key features include power windows, cruise control, and an advanced audio system. The sedan and coupe models offer comfortable seating for up to five passengers, with optional upgrades like heated seats and a leather-trimmed interior for enhanced comfort and style.

Exterior Features

The 2010 Honda Accord manual details its sleek and aerodynamic exterior design. Available in sedan and coupe styles, it features halogen headlights, a chrome grille, and a trunk lid spoiler for a sporty appearance. Alloy wheels enhance both style and performance, while optional upgrades like a power moonroof with tilt functionality add convenience and sophistication to the vehicle’s exterior.

Maintenance and Care

Regular maintenance is crucial for the 2010 Honda Accord’s longevity. Schedule oil changes, tire rotations, and fluid checks as outlined in the owner’s manual for optimal performance.

Regular Maintenance Schedule

Adhere to the 2010 Honda Accord’s recommended maintenance schedule for optimal performance. Oil changes are required every 5,000 miles, while tire rotations should occur every 8,000 miles. Additional checks include brake pads, air filters, and fluid levels. Refer to the owner’s manual for detailed intervals and procedures to ensure longevity and reliability of your vehicle;

DIY Maintenance Tips

Perform regular checks on windshield washer fluid, wiper blades, and belts. Replace the air filter every 15,000 miles to improve fuel efficiency. Check and top off fluids like coolant and brake fluid as needed. Inspect tire pressure monthly and maintain recommended levels. These simple tasks can enhance performance and prevent costly repairs, ensuring your Honda Accord runs smoothly for years.

Troubleshooting Common Issues

Diagnose issues like diagnostic codes or engine knocks using the manual’s guidelines. Refer to the troubleshooting section for solutions to common problems, ensuring proper fixes and prevention.

Common Problems and Solutions

Common issues in the 2010 Honda Accord include diagnostic codes like P00AF for turbo boost and engine knocks. Solutions involve consulting the manual for guidance, using recommended fuel, and addressing maintenance promptly. Regular checks and adhering to manual instructions help prevent and resolve these issues effectively, ensuring optimal performance and longevity of the vehicle.

Diagnostic Techniques

The 2010 Honda Accord manual highlights diagnostic techniques like checking diagnostic codes such as P00AF for turbo boost issues. It also emphasizes using tools like OBD-II scanners for detailed diagnostics. Regular inspections of fluid levels, battery health, and brake systems are recommended. The manual provides guidance on interpreting these diagnostics to prevent damage and ensure proper vehicle maintenance, aligning with the car’s service-related devices that record performance data.

Safety Features

The 2010 Honda Accord manual details advanced safety features, including multiple airbags, anti-lock braking systems, and structural enhancements to ensure occupant protection and vehicle stability in various conditions.

Active Safety Features

The 2010 Honda Accord manual highlights active safety features like anti-lock braking system (ABS) with electronic brake distribution (EBD) and vehicle stability assist (VSA). These systems enhance control during braking and cornering, reducing skidding risks. Dual front airbags and active head restraints also contribute to occupant protection. The manual emphasizes proper use and maintenance of these features for optimal safety performance and driver confidence.

Passive Safety Features

The 2010 Honda Accord manual details passive safety features, including dual front airbags, front side airbags, and side curtain airbags for enhanced occupant protection. The advanced compatibility engineering (ACE) body structure helps distribute crash energy, reducing the risk of injury. Active head restraints and a reinforced frame further enhance safety. These features work together to provide a secure environment for drivers and passengers in the event of a collision.

Accessories and Upgrades

Explore a variety of accessories and upgrades for the 2010 Honda Accord, such as roof racks, alloy wheels, and performance-enhancing parts, to customize your vehicle.

Recommended Accessories

For the 2010 Honda Accord, recommended accessories include roof racks for luggage or bike mounts, alloy wheels for enhanced style, and performance upgrades like air intake systems. Additionally, cargo nets, car covers, and trunk organizers can improve functionality. Tech accessories such as phone mounts and USB chargers are also popular for modern convenience. These items enhance both aesthetics and practicality, allowing owners to customize their vehicle to their preferences.

Performance Upgrades

Performance upgrades for the 2010 Honda Accord manual can include installing a cold air intake or performance exhaust to enhance horsepower and torque. Upgrading the suspension with stiffer springs or shocks improves handling. Lightweight alloy wheels and high-performance tires can also boost agility. Additionally, ECU tuning and aftermarket engine components can further optimize power output, ensuring a smoother and more responsive driving experience for enthusiasts.

Technical Specifications

The 2010 Honda Accord manual provides detailed specs, including engine options like 4-cylinder or V6, body styles (sedan, coupe), wheelbase (110.2 inches), and curb weight (3,200–3,600 lbs).

Vehicle Dimensions

The 2010 Honda Accord’s dimensions include a wheelbase of 110.2 inches and overall length of 191.8 inches. Sedan width is 72.7 inches, while coupe measures 72.2 inches. Height for sedans is 57.7 inches, and coupes stand at 56.4 inches. These measurements ensure a balanced design, optimizing space and aerodynamics for both styles, as detailed in the manual.

Weight and Capacity

The 2010 Honda Accord’s curb weight ranges from approximately 3,184 to 3,457 pounds, depending on the trim. The sedan offers a trunk capacity of 14 cubic feet, while the coupe provides 11.9 cubic feet. The fuel tank capacity is 18;5 gallons. Towing capacity, when properly equipped, is up to 1,000 pounds, as specified in the manual for safe and efficient vehicle operation.

Warranty and Support

The 2010 Honda Accord manual includes warranty details and support options, ensuring owners have access to necessary information for maintenance and repairs, as specified online.

Factory Warranty Details

The 2010 Honda Accord manual outlines the factory warranty, which includes coverage for parts and labor, offering protection against defects for a specified period or mileage. This ensures owners can address issues without additional costs, providing peace of mind and financial security during the initial ownership period, as detailed in the manual.

Customer Support Options

Honda provides comprehensive customer support options for 2010 Accord owners, including online resources, FAQs, and troubleshooting guides. Owners can access the official Honda website for detailed assistance, diagnostic tools, and direct contact with support specialists. Additionally, community forums and authorized dealers offer further assistance, ensuring prompt resolution of queries and concerns related to the vehicle’s operation and maintenance.

Digital Resources

The 2010 Honda Accord manual is available online as a downloadable PDF, offering easy access to guides, troubleshooting, and maintenance tips. Community forums and FAQs provide additional support, ensuring owners can resolve issues efficiently and stay informed about their vehicle’s operation and care.

Online Manual and Guides

The 2010 Honda Accord manual is readily available online as a downloadable PDF, accessible through platforms like CarManualsOnline.info. Official Honda websites and forums also provide digital versions, ensuring easy access to detailed guides, troubleshooting tips, and maintenance schedules. These resources allow owners to search for specific information quickly, aiding in DIY repairs and enhancing overall vehicle maintenance efficiency.

Community Forums and FAQ

Online forums and FAQ sections dedicated to the 2010 Honda Accord provide valuable insights from experienced owners and technicians. Communities like Reddit’s r/carIndia and Honda-specific forums offer troubleshooting tips, DIY guides, and discussions on common issues. These platforms also host detailed FAQs, addressing maintenance, repairs, and upgrades, helping owners resolve problems efficiently and stay informed about best practices for their vehicle.

The 2010 Honda Accord manual serves as an indispensable resource for owners, offering detailed insights into operation, maintenance, and troubleshooting. By following the guidelines, drivers can maximize performance, safety, and longevity of their vehicle. Regular updates and community support further enhance the ownership experience, ensuring the Accord remains a reliable and enjoyable choice for years to come.